Tariffs Were Supposed to Revive U.S. Manufacturing, but So Far Have Had the Opposite Effect

Key Points

- Despite some improvement in manufacturing activity in August, a survey of manufacturing managers shows that tariffs are putting pressure on their businesses.

- Manufacturers report that import tariffs are impacting supply chains, and the uncertainty of tariff policy changes has caused many customers to delay purchases.

- Respondents say that tariffs have driven up raw material costs, making it more difficult to manufacture products in the United States.

Theoretically, the U.S. imposing tariffs on foreign imports should have one benefit—stimulating domestic manufacturing growth. But so far, the effects of tariffs seem to be quite the opposite.

A widely watched manufacturing survey shows that despite some signs of improvement, U.S. manufacturing contracted for the sixth consecutive month in August. In addition, the data indicates that manufacturers are struggling to cope with the impact of tariffs while also dealing with rising raw material prices and reduced spending from cautious buyers.

The Institute for Supply Management (ISM) reported that the Manufacturing Purchasing Managers' Index (PMI) rose to 48.7 in August, but remained below the threshold of 50 that signals industry expansion. The data suggests that high input costs and increased supply chain pressures caused by tariffs have offset improvements in new orders and employment levels.

Wells Fargo economists Shannon Grein and Tim Quinlan wrote: "Uncertainty around tariff policy is limiting industry activity. While the increased costs associated with tariffs are a challenge, the uncertainty about where tariffs will ultimately be set may be an even greater constraint on current industry activity."

High Costs Drag Down Domestic Manufacturing

Business leaders participating in the survey said they are feeling the impact of tariffs. Some companies noted that although the policy aims to bring factories back to the U.S., rising costs are making domestic manufacturing even more difficult.

A respondent from a computer and electronic products company said: "Tariffs continue to disrupt planning and scheduling. Plans to move production back to the U.S. are affected by rising raw material costs, making it harder to justify the move."

Some tariffs target goods from specific countries, such as the recent 50% tariff on Indian goods; others target raw materials like metals and lumber.

A manufacturer of electrical equipment and household appliances stated in the survey: "With many components subject to tariffs, 'Made in America' has become even more difficult." The company also noted that it has laid off about 15% of its U.S. workforce: "The government wants manufacturing jobs to stay in the U.S., but we are losing higher-skilled, higher-paid positions. In the absence of trade and economic stability, capital expenditures and hiring have stalled."

Economists say that U.S. manufacturing may remain in a low-growth state throughout this year. However, if several recent court rulings unfavorable to tariffs are upheld, it could provide some relief for manufacturers.

BMO Chief U.S. Economist Scott Anderson wrote: "If recent court rulings declaring reciprocal tariffs illegal result in the removal of some tariffs and thus ease tariff pressures, the outlook for manufacturing could further improve."

Disclaimer: The content of this article solely reflects the author's opinion and does not represent the platform in any capacity. This article is not intended to serve as a reference for making investment decisions.

You may also like

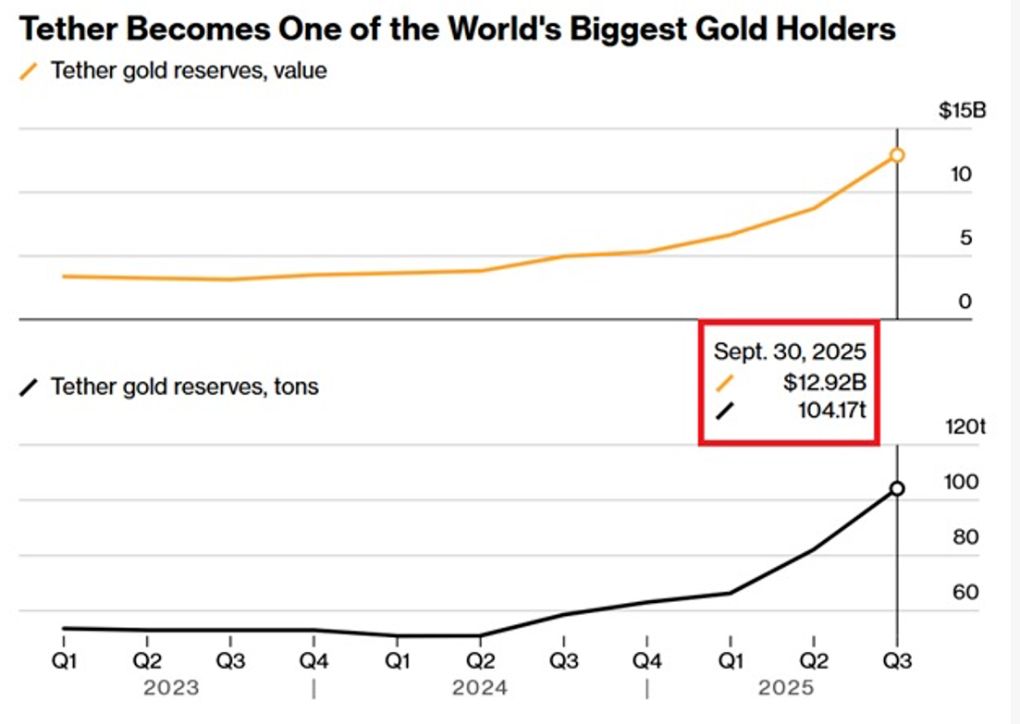

Digital dollar hoards gold, Tether's vault is astonishing!

The Crypto Bloodbath Stalls: Is a Bottom In?

Can the 40 billion bitcoin taken away by Qian Zhimin be returned to China?

Our core demand is very clear—to return the assets to their rightful owners, that is, to return them to the Chinese victims.